The Cutting Edge: How VG-10 Steel is Transforming the World of Professional Hair Shears

VG-10 steel is not just a material; it's a narrative of innovation, craftsmanship, and precision. Originating in Japan, this high-carbon stainless steel has found applications in various industries, from cutlery to aerospace. However, one of its most compelling uses is in the crafting of professional hair cutting scissors and shears. The journey of VG-10 steel from ore to shear is a captivating tale that combines ancient Japanese traditions with modern metallurgical science. In this article, we will explore the origins, properties, and manufacturing process of VG-10 steel, and delve into why it has become a sought-after material for high-quality hair cutting tools.

The Origins of VG-10 Steel

VG-10 steel was developed in Japan, a country with a rich history of metallurgy and craftsmanship. The name "VG-10" stands for V Gold 10 ("gold" indicating quality), and it is often referred to as a "super steel" because of its exceptional properties. Unlike other types of steel, VG-10 offers a unique blend of hardness, corrosion resistance, and edge retention, making it highly versatile.

The development of VG-10 steel was a milestone in the Japanese steel industry, marking a shift from traditional steels like Tamahagane, used in Samurai swords, to modern, high-performance steels. While VG-10 may not share the historical prestige of Tamahagane, it embodies the same commitment to quality and excellence that has defined Japanese craftsmanship for centuries.

The Japanese Philosophy of Craftsmanship

In Japan, craftsmanship goes beyond skill; it's a way of life. The term "Monozukuri" captures this philosophy, emphasizing the spirit and process involved in making things, not just the end product. This ethos is deeply embedded in the Japanese steel industry, where meticulous attention to detail is a given.

From the selection of raw materials to the intricate heat treatment processes, each step in the production of VG-10 steel is carried out with a level of care that reflects both ancient traditions and modern technological advancements. The craftsmen involved are often considered artisans, honing their skills through years of training and practice. Their expertise ensures that VG-10 steel meets the high standards set by both history and contemporary needs.

Mining and Sourcing the Minerals

The tale of VG-10 steel starts deep within the Earth, where essential minerals like iron, chromium, and vanadium are found. While Japan is not particularly abundant in these natural resources, it has a long history of sourcing high-quality minerals through both domestic mining and international partnerships. The minerals are carefully selected to meet the specific requirements of VG-10 steel, which is known for its unique alloy composition.

The mining process is a blend of traditional techniques and modern technology. Once the ore is extracted, it undergoes rigorous testing to determine its quality and composition. This is a crucial step, as the purity of the minerals significantly impacts the final characteristics of the steel. The ore is then processed to isolate the valuable minerals, setting the stage for the next phase: metallurgy.

The Metallurgy of VG-10

The smelting process is where the magic happens. In specialized furnaces, the raw minerals are melted at extremely high temperatures to form a homogeneous liquid metal. Alloying elements like chromium, for corrosion resistance, and vanadium, for increased hardness and toughness, are added at this stage. VG-10 steel typically contains about 1% carbon, 15% chromium, and a small amount of vanadium, among other elements.

Heat treatment follows the smelting process, and it's here that VG-10 steel gains its renowned properties. The steel is subjected to a series of thermal cycles to harden it, improve its structure, and enhance its mechanical properties. Japanese craftsmen have mastered the art of heat treatment, often using proprietary techniques to achieve the perfect balance of hardness, toughness, and corrosion resistance.

Manufacturing VG-10 Steel Products

Once the VG-10 steel has been smelted and treated, it's time to shape it into usable forms. This involves various processes like forging, rolling, and cutting. In Japan, even these seemingly routine tasks are performed with an extraordinary level of skill and precision. Special techniques, often unique to individual manufacturers, are employed to ensure that the steel meets the exacting standards required for professional tools like hair cutting scissors and shears.

Quality control is a cornerstone of Japanese manufacturing, and VG-10 steel is no exception. Each batch undergoes stringent testing to ensure it meets or exceeds the required specifications. From hardness tests to evaluations of corrosion resistance, every aspect is scrutinized to ensure the highest quality.

VG-10 Steel in Hair Cutting Scissors and Shears

The culmination of VG-10 steel's journey is its application in professional hair cutting scissors and shears. But what makes this steel so ideal for this specific use? The answer lies in its unique combination of properties. Hair cutting tools require a material that is hard enough to maintain a sharp edge, yet flexible enough to withstand the stresses of daily use. VG-10 steel's high carbon content ensures excellent hardness, while its alloying elements like vanadium contribute to its toughness.

When compared to other types of steel, VG-10 often stands out as the material of choice for hair cutting tools. Its unique balance of hardness, sharpness, and durability has garnered praise from industry experts and hairstylists alike. Testimonials often highlight the noticeable difference in performance, longevity, and ease of maintenance when using scissors and shears made from VG-10 steel.

The Science Behind the Shear

The science of hair cutting is more nuanced than it may appear. A pair of scissors or shears must be sharp enough to make clean, precise cuts, hard enough to maintain that sharpness, and durable enough to withstand the rigors of daily use. VG-10 steel excels in all these areas. Its hardness often exceeds 60 HRC (Rockwell Hardness Scale), making it one of the hardest steels suitable for hair cutting tools. This hardness ensures that the tools remain sharp for extended periods, reducing the need for frequent sharpening and thereby extending their lifespan.

Ergonomics is another critical factor in the design of hair cutting scissors and shears. The weight, balance, and handling of the material can significantly impact a hairstylist's work quality and comfort. VG-10 steel offers an excellent strength-to-weight ratio, allowing for the creation of tools that are both robust and comfortable to use. This is particularly important for professionals who use these tools for extended periods, as it minimizes hand fatigue and strain.

Sustainability and Environmental Concerns

The production of steel, including VG-10, is energy-intensive and has environmental implications. However, Japan has been proactive in implementing sustainable practices in its steel industry. From energy-efficient smelting techniques to recycling programs, efforts are being made to minimize the environmental impact of steel production.

Moreover, the longevity of VG-10 steel products adds an element of sustainability. High-quality scissors and shears made from this material can last for years, if not decades, with proper care. This durability reduces the need for frequent replacements, conserving resources, and minimizing waste.

The journey of VG-10 steel is a compelling narrative that spans from the mines to the salons, embodying the essence of Japanese craftsmanship and innovation. This high-carbon stainless steel, with its unique blend of hardness, toughness, and corrosion resistance, stands as a testament to Japan's enduring commitment to quality and excellence.

In the realm of professional hair cutting scissors and shears, VG-10 steel has found its perfect application. It offers hairstylists and barbers a tool that not only performs exceptionally but also lasts. The marriage of tradition and technology in this remarkable material ensures that the Japanese spirit of precision and excellence continues to live on in each snip and cut.

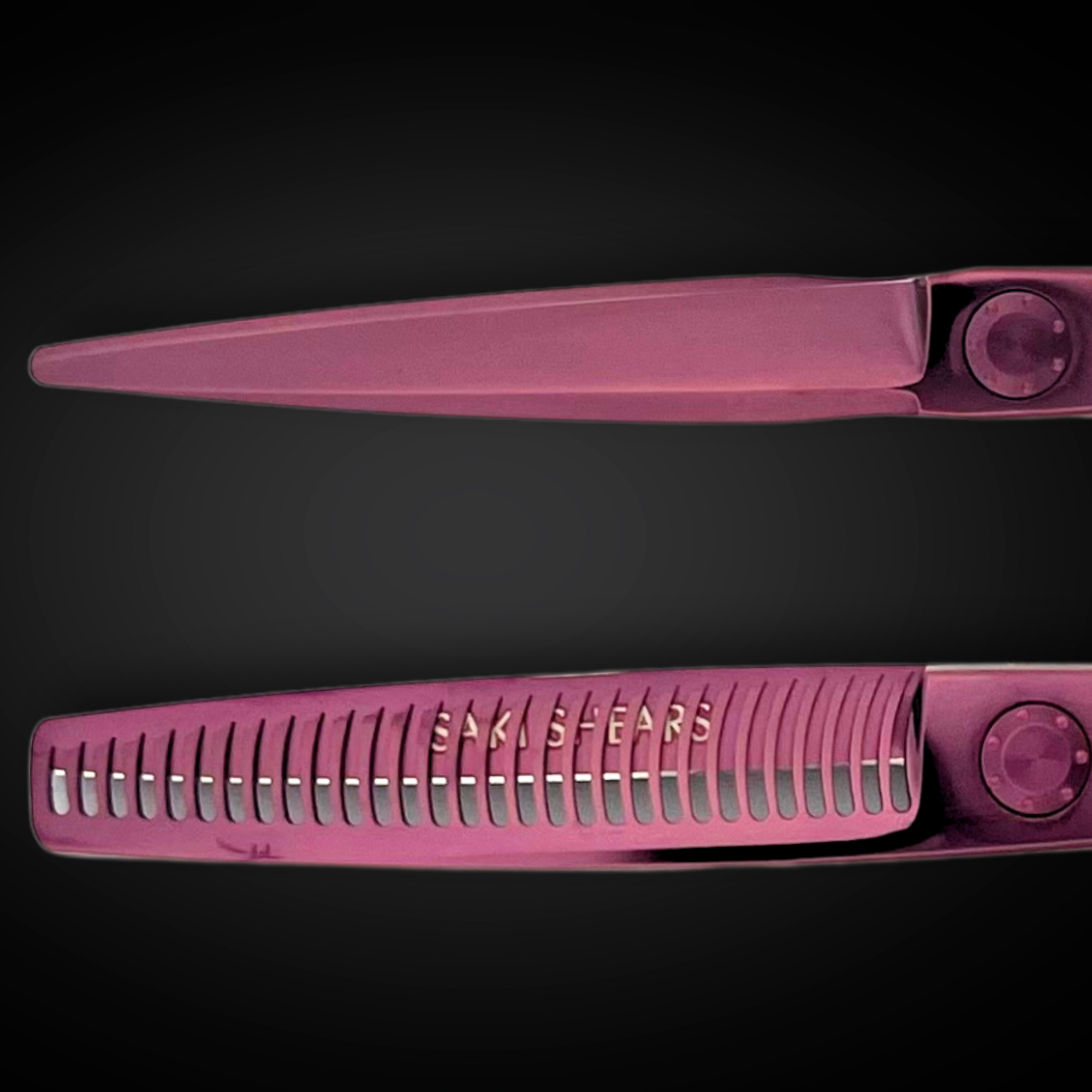

At Saki Shears, the choice to use VG-10 steel in many of our professional hair shears is rooted in a commitment to delivering unparalleled quality and performance. VG-10 steel, renowned for its exceptional hardness, edge retention, and corrosion resistance, aligns perfectly with our ethos of providing hairstylists and barbers with tools that not only excel in function but also stand the test of time. This high-carbon stainless steel allows us to create shears that are incredibly sharp, yet durable—qualities that are essential for professionals who demand the best in their daily work.

The decision to use VG-10 steel also reflects our respect for the rich tradition of Japanese craftsmanship. By employing a material that embodies the Japanese philosophy of "Monozukuri," or the art of making things, we ensure that each pair of Saki Shears is a masterpiece of both form and function. The VG-10 steel undergoes a meticulous heat treatment process, honed by generations of Japanese artisans, to achieve its remarkable properties. This results in shears that offer an exceptional cutting experience, minimal maintenance, and a longevity that makes them not just a tool, but an investment in your craft.