7 Signs Your Hair Cutting Shears Need Maintenance

Your hair cutting shears are essential tools, and their performance directly impacts your work quality and client satisfaction. Neglecting maintenance can lead to dull blades, uneven cuts, and even physical strain. Here are the 7 key signs your shears need attention:

- Dull Blades: Hair pushes or snags instead of cutting cleanly.

- Uneven Cutting: Misaligned blades or incorrect tension cause inconsistent results.

- Difficult Handling: Stiff movement or loose screws make shears harder to use.

- Hair/Product Buildup: Residue between blades reduces cutting precision.

- Rust or Corrosion: Moisture damage affects blade sharpness and durability.

- Excessive Effort Needed: Cutting feels harder, leading to hand fatigue.

- Jagged Blade Edges: Worn blades result in rough cuts and damage to hair.

Quick Fixes: Regular cleaning, lubrication, tension checks, and professional sharpening every 6–12 months can keep your shears in top condition. Proper storage and daily care also prevent costly repairs or replacements.

How To: Check and Adjust Your Shear Tension

1. Dull Blades

Dull blades are a clear sign your shears need some care. They can ruin the precision of your cuts, affect your clients' satisfaction, and even harm your professional image.

Signs Your Blades Are Dull

Here’s how to tell if your blades have lost their edge:

- Hair strands push away instead of cutting cleanly.

- Cuts leave behind frayed or split ends.

- You feel pulling or snagging during a cut.

- Precision work becomes a struggle or feels impossible. [1][7]

How to Fix Dull Blades

To keep your shears in top shape, follow this maintenance routine:

- Daily: Clean and lubricate your shears.

- Weekly: Check and adjust the tension.

- Every 500-700 haircuts: Get them professionally sharpened. [1][2]

Additional tips to protect your tools:

- Store your shears in a protective case when not in use.

- Use them only for cutting hair - no exceptions.

- Clean them after each use to remove any residue. [2][7]

Even with daily upkeep, professional sharpening is essential. Regular maintenance by a qualified service will keep your shears performing at their best and extend their lifespan. This small investment ensures consistent, high-quality results for your clients.

While dull blades are a frequent issue, uneven cutting can also point to maintenance needs.

2. Uneven Cutting

Uneven cutting is a clear sign that your shears need attention. It not only affects the quality of your work but can also harm your clients' hair and impact your professional reputation.

How Tension Impacts Cutting

The tension of your shears plays a big role in their performance. If the tension is too loose, the blades may separate, causing hair to slip. If it's too tight, the extra friction makes cutting more difficult and can even damage hair [2]. A properly tensioned pair of shears should produce a crisp, clean sound when cutting. If you hear pulling or scratching noises, it’s likely a tension issue [9].

Fixing Uneven Cutting

Addressing Tension Issues: Start by cleaning and lubricating your shears. Then, adjust the tension screw in small quarter-turns until the cutting feels smooth [2].

Dealing with Blade Alignment: If adjusting the tension doesn’t solve the problem, the blades might be misaligned. Regular professional servicing, ideally every 6-12 months, helps maintain proper alignment and avoids problems like [2][9]:

- Uneven cut lengths

- Hair pulling or snagging

- Extra strain on your hand during use

Avoid attempting major repairs on your own, as this can cause further damage. When in doubt, consult a professional shear maintenance expert to diagnose and fix the issue.

While uneven cutting is often linked to tension or alignment problems, it could also indicate other maintenance needs.

3. Handling Feels Difficult

If your shears are becoming harder to handle, it's a clear indication they need attention. Smooth handling is key - not just for precise cuts, but also for your comfort during long styling sessions.

Common Handling Issues

Here are some common problems that can make your shears tricky to use:

- Stiff Movement: Often caused by a lack of lubrication or debris around the pivot point, this can lead to hand strain and less accurate cuts [1].

- Loose Components: A loose pivot screw can make your shears wobbly, reducing control and potentially damaging the blades [2].

- Discomfort: If you feel strain in your hand or wrist, it could point to alignment issues that need professional attention [4].

Fixing these issues early not only makes your work easier but also helps your shears last longer.

Tips for Better Handling

Keep your shears performing at their best with these maintenance habits:

-

Daily Care:

"Clean and sanitize your shears after every cut." [5]

This prevents buildup and keeps them running smoothly. - Lubrication and Servicing: Apply lubrication weekly to reduce friction and ensure smooth operation. Schedule professional servicing every 6–12 months to address tension and alignment problems that regular care can’t fix [7] [10].

- Proper Storage: Store your shears in a safe, dry place to avoid damage from accidental drops or humidity, which can affect their performance [8].

While mechanical issues are often the main cause of handling problems, external factors like buildup can also interfere with how well your shears work. Stay on top of maintenance to avoid interruptions.

4. Hair and Product Buildup

Hair and product buildup is a frequent problem that can make even the best shears less effective. Hair particles, styling products, and natural oils tend to gather between the blades and around the pivot point. This creates friction, reduces accuracy, and wears down the blades faster. If left unchecked, this debris can disrupt the smooth operation of your shears and impact their cutting ability [1].

How Buildup Impacts Shears

When buildup occurs, it leads to several issues that can hurt your shears' performance:

- More Friction: Residue causes resistance between the blades, making cutting harder.

- Loss of Accuracy: Buildup can cause hair to fold instead of being cut cleanly.

- Faster Wear and Tear: The strain from residue speeds up blade deterioration.

Proper Cleaning for Shears

Keeping your shears clean is crucial for maintaining their precision and durability. Here’s a simple cleaning routine:

- After each use: Wipe the blades with a soft cloth to remove debris.

- Daily: Wash your shears with warm water and mild soap.

- Weekly: Use a few drops of high-quality shear oil to ensure smooth operation.

To clean your shears effectively, follow these steps:

- Wash both blades and the pivot area with warm water and mild soap [9].

- Dry thoroughly with a lint-free cloth to prevent rust [1].

- Apply a few drops of shear oil to keep the blades moving smoothly [9].

Avoid using harsh chemicals or abrasive materials, as they can damage the blades. Store your shears in a case that absorbs moisture to prevent debris buildup between uses [1].

Skipping regular cleaning doesn’t just affect performance - it can lead to bigger problems like rust or corrosion over time.

sbb-itb-3cc0078

5. Rust or Corrosion

Rust and corrosion can cause lasting damage to hair cutting shears, affecting their look and performance. Unlike other maintenance concerns, rust demands immediate attention to avoid permanent harm.

How to Spot and Avoid Rust

Signs of rust include:

- Orange-brown spots on the blades

- Rough or uneven textures

- Stiff movement when opening or closing

- Dark discoloration on metal surfaces

Rust commonly forms in areas prone to moisture buildup, such as pivot points, blade edges, and handle joints [1]. Addressing rust early is crucial, as severe cases often require replacing the blades entirely [2].

Practical Steps to Prevent Rust

- Dry Thoroughly: After cleaning, use a microfiber cloth to dry your shears, especially around pivot points and joints [1].

- Store Correctly: Use a case that keeps tools dry, preferably one with moisture-absorbing features [10].

- Maintain Regularly: Apply high-quality shear oil weekly and inspect your tools for early signs of rust [1][2].

Additional tips:

- Clean shears after every use.

- Use oils specifically made for hair cutting tools.

- Keep shears away from water when not in use [1].

Preventing rust helps extend the life of your shears and ensures consistent cutting performance. Minor rust spots can often be handled with professional maintenance, but severe corrosion may mean replacement is necessary [2].

While rust is a serious issue, another factor that can impact your cutting tools is the need for excessive force.

6. Cutting Requires More Effort

If you notice cutting takes more effort than usual, it’s a clear sign your shears might need maintenance. Ignoring this can lead to reduced precision, hand fatigue, and even permanent damage to your tools [1].

Signs Your Shears Need Attention

Here are some red flags that indicate your shears require maintenance:

- Hair pushes or pulls instead of cutting cleanly: This happens when the blades lose their sharpness or alignment [4].

- Hand strain or discomfort: Cutting feels harder on your hands and wrists than it should.

- Uneven cuts: You struggle to achieve smooth, continuous motions.

- Resistance when closing blades: The motion feels rough or stiff instead of smooth [1].

These issues often result from buildup, misaligned blades, or incorrect tension settings. If ignored, they can shorten your shears' lifespan and lower the quality of your work [2][11].

Tips to Make Cutting Easier

To keep your shears in top condition, routine maintenance is key. Here’s what you can do:

| Task | How Often | Why It Helps |

|---|---|---|

| Sharpening & Tension Checks | Sharpen every 6-12 months; check tension weekly | Keeps the blades sharp, reduces resistance, and ensures smooth operation. |

| Lubrication | After each cleaning | Minimizes friction, making the cutting process smoother. |

Extra force isn’t just inconvenient - it’s a warning sign. Addressing these problems early ensures your shears stay reliable and protects your investment in professional tools [11].

Failing to resolve these issues can also cause blade damage, such as jagged edges. We’ll cover this critical problem in the next section.

7. Jagged Blade Edges

Jagged blade edges can seriously affect the quality of your haircuts and even harm your clients' hair. These issues often arise from skipped maintenance and need immediate attention to fix [1].

What Jagged Edges Indicate

Jagged edges develop over time due to wear and tear, impacting both your work and your clients' results. Here’s a breakdown of common causes and their effects:

| Cause | Impact | Warning Signs |

|---|---|---|

| Buildup & Poor Cleaning | Friction leads to uneven cuts and rough results | Hair looks uneven or rough [4] |

| Normal Wear and Tear | Reduces cutting precision | Blades feel resistant during use |

| Misaligned Blades | Affects cutting accuracy | Inconsistent cutting performance |

These issues don’t just compromise your work - they can also damage your clients' hair, causing split ends and uneven cuts [11].

Fixing Jagged Edges

The best solution is professional sharpening, which restores your blades to their original condition. Here’s a suggested maintenance routine:

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Professional Sharpening | Every 6-8 months | Fix jagged edges and restore precision |

| Cleaning & Lubrication | After each use/weekly | Prevent buildup and reduce friction |

| Blade Inspection | After each use | Spot early signs of wear or damage |

To keep your shears in top shape between professional sharpening:

- Clean them thoroughly after each use [5].

- Adjust tension regularly to maintain proper alignment [12].

- Apply lubricant weekly to reduce friction and protect the blades [5][6].

Avoid sharpening blades yourself - it can cause permanent damage. Always rely on professional services to keep your tools sharp and effective [2][11].

Key Tips for Maintaining Your Shears

Why Regular Maintenance Matters

Keeping your shears in good shape is crucial. It ensures accurate cuts, makes your tools last longer, and reduces strain on your hands. Plus, it helps you avoid problems like rust and buildup before they get worse.

"Shears are a big investment and by taking care of them you're getting the most out of your investment" [5].

| Area | Benefit |

|---|---|

| Performance | Delivers precise, clean cuts |

| Longevity | Extends the lifespan of your tool |

| Safety | Reduces hand strain and improves control |

Suggested Maintenance Schedule

Following a consistent care routine can save you from expensive repairs or replacements. Here's a practical guide:

| Timeframe | Task | Why It’s Important |

|---|---|---|

| Daily | Clean blades, check tension, and store properly | Keeps cuts accurate and removes debris [1][2] |

| Weekly | Apply oil and deep clean | Ensures smooth use and prevents rust [5][6] |

| Monthly | Inspect blades and screws | Identifies wear and tear early [6] |

| Every 6-12 months | Professional sharpening | Restores peak cutting performance [2][3] |

To get the best results from your shears, keep these tips in mind:

- Use only products recommended by the manufacturer.

- Always store your shears with the blades closed.

- Avoid sharing your tools to maintain their condition. [1][2][3]

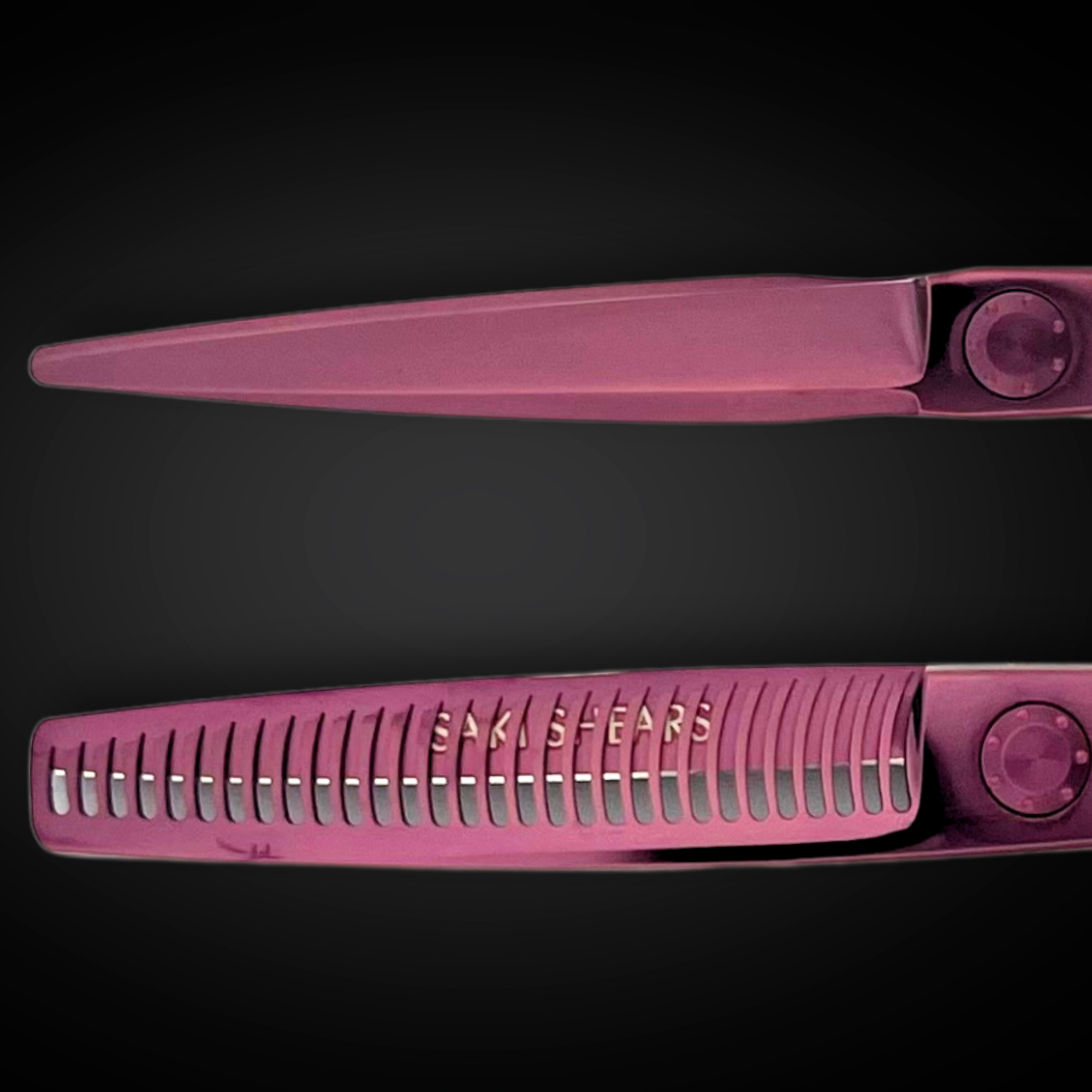

Check Out Saki Shears for Professional Tools and Care

If you're a stylist looking for reliable tools and easy maintenance solutions, Saki Shears offers a wide range of products tailored to meet the needs of professionals.

Why Choose Saki Shears

Saki Shears focuses on creating tools that combine excellent materials with thoughtful design. Their shears are made from premium Japanese steel, offering long-lasting sharpness and precision. Plus, features like adjustable tension and ergonomic handles ensure both comfort and control. Each pair is also protected by a lifetime warranty.

Highlights of Saki Shears:

- Built with durable Japanese steel

- Designed to minimize hand fatigue

- Maintains sharp, precise cuts

- Resistant to rust and wear

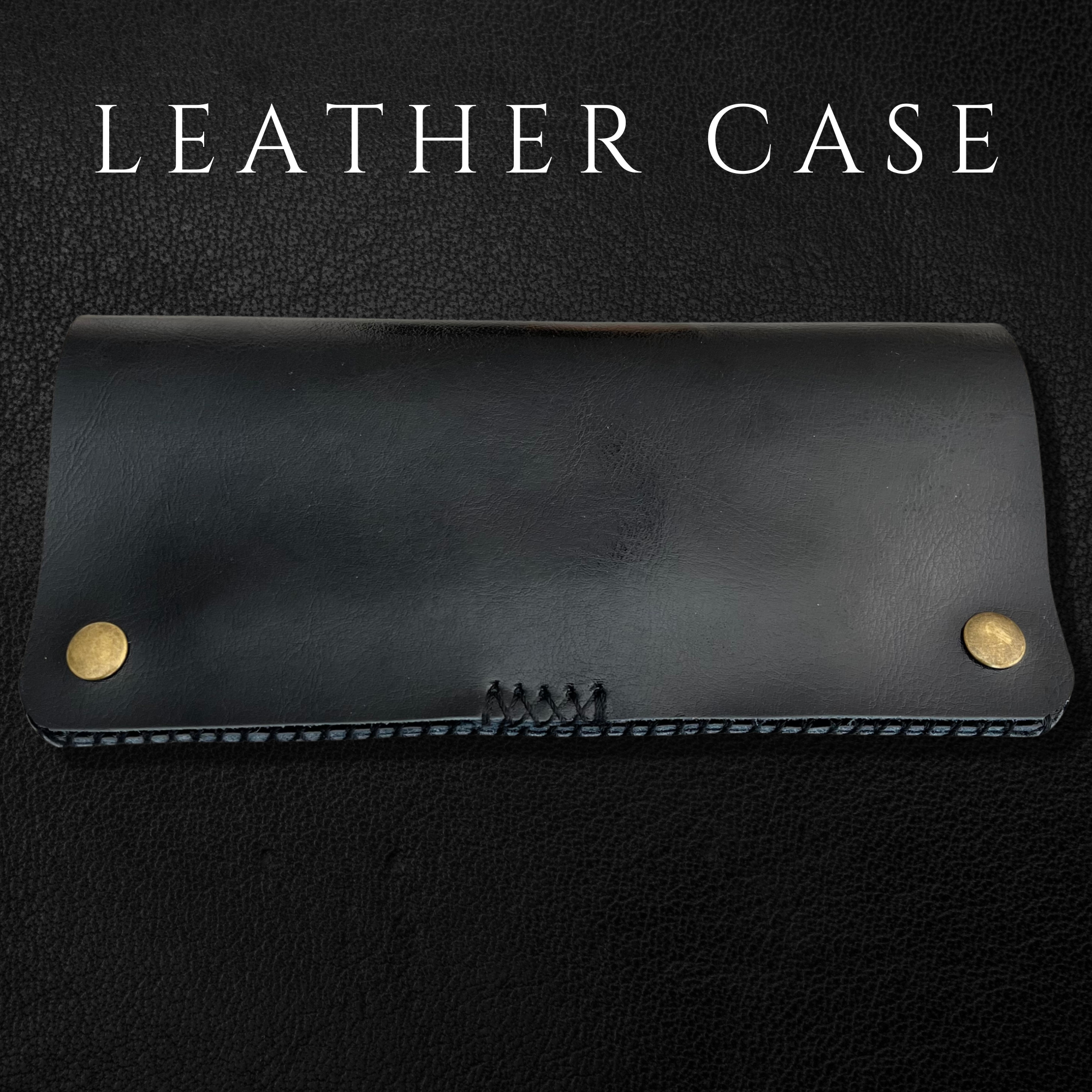

Maintenance Tools from Saki Shears

"Regular maintenance using proper tools and techniques is crucial for extending the life of your shears and maintaining their cutting precision", states Saki Shears' maintenance guide [6].

Saki Shears provides maintenance tools designed specifically for professionals. Their care products include cleaning kits, lubricants, tension adjusters, and storage cases, all aimed at making upkeep simple and effective.

These tools make it easy to:

- Remove hair and product buildup

- Keep shears operating smoothly

- Adjust tension for better cutting performance

- Safeguard tools during storage and transport

With these solutions, maintaining your shears becomes a seamless part of your routine.

FAQs

Here are answers to some common questions about maintaining your hairdressing shears.

How often should you sharpen hairdressing scissors?

You should sharpen your hairdressing scissors every 6 to 12 months, depending on how often you use them. If you frequently cut dry or chemically-treated hair, sharpening closer to the 6-month mark is recommended [2].

Factors like client volume, cutting techniques, hair types, and the quality of your shears also affect how often sharpening is needed.

How do you maintain shears?

Daily Care:

- Clean with soap and water, dry completely, and sanitize after each use [1].

Weekly Maintenance:

- Apply lubrication to the pivot screw.

- Check the tension to ensure proper alignment.

- Look for any signs of wear or damage [6].

Storage Tips:

- Keep your shears in a case with moisture-absorbing features to prevent rust.

- Store them in a dry area.

- Avoid sharing your tools to maintain hygiene [2].