Dropped Shears: Damage Assessment Tips

Dropping your hair shears can lead to serious issues like misaligned blades, chips, or even structural damage. Here's what you need to know to protect your tools and keep them in top condition:

- Inspect Immediately: Check for visible cracks, dents, or scratches. Test blade alignment by opening and closing the shears slowly. Look for chips or dull spots on the edges.

- Handle with Care: Avoid further damage by keeping blades apart and wrapping the shears in a soft cloth.

- Seek Professional Repair: Even small issues like loose screws or misaligned blades should be addressed by a repair specialist.

- Prevent Future Damage: Use proper storage (like cases or holsters), clean and oil regularly, and invest in durable, high-quality shears made from materials like Japanese steel.

Quick Tip: Acting fast after a drop can prevent minor issues from turning into costly repairs. Regular maintenance and safe handling will also extend the life of your shears.

What To Do If You Drop Or Damage Your Hair Shear

How to Check for Damage After Dropping Shears

Dropping your shears can be stressful, but a careful inspection can help you address any potential issues. Use this guide to evaluate your tools and decide on the next steps.

Look for Visible Damage

Start by examining the shears for cracks, dents, or scratches on the handles, blades, and screws. Pay close attention to how light reflects on the surface - uneven reflections might signal damage. Make sure to check in a well-lit area to spot any imperfections [2][4].

Check Blade Alignment

Open and close the shears slowly, noting any unusual resistance or a "jumping" sensation. These are common signs of misalignment [2]. If you feel grinding or uneven movement, there could be internal damage that needs professional repair. Misaligned blades can also put stress on other parts, like the handles or finger rests.

Inspect Blade Edges for Chips or Dull Spots

Carefully examine the cutting edges for chips, nicks, or dull areas that could impact performance [2][4]. If you find a chip, wrap the shears to keep the blades apart and avoid causing more damage.

| Damage Type | Signs | Next Steps |

|---|---|---|

| Visible Damage | Cracks, dents, scratches | Note the location and severity |

| Misalignment | Uneven movement, jumping motion | Keep blades separated |

| Edge Issues | Chips, nicks, dull spots | Wrap in protective material |

Even if everything looks fine, internal problems could still exist. It's a good idea to have your shears professionally inspected after a significant drop. Acting quickly can help prevent further damage and keep your tools in top condition [2].

What to Do Right After Dropping Your Shears

Acting quickly after dropping your shears can help minimize damage and keep them in working condition.

Handle with Care

Pick up your shears carefully to avoid causing more harm. Keep the blades apart and wrap them in a soft cloth or bubble wrap for safe temporary storage until they can be inspected by a professional [4].

Consult a Repair Specialist

Even if the damage isn't obvious, getting a professional assessment is crucial. A skilled bladesmith can check for internal issues, realign the blades, and fix tension problems. Hidden problems like slight misalignments or tiny dents can lead to uneven cuts and might even pose risks to your clients if ignored [4].

When choosing a repair expert, look for someone experienced in handling high-quality hair shears. Many professionals can handle common problems like bent blades, loose screws, and small dents or cracks [1][4].

Once your shears are stored safely, getting them professionally repaired should be your next move to bring them back to peak performance.

sbb-itb-3cc0078

How Professionals Repair Dropped Shears

Experts rely on specialized tools and techniques to bring dropped shears back to their best condition. Their skill ensures repairs are precise, preventing further harm and restoring the shears' performance.

Sharpening and Realigning Blades

When shears are dropped, even slight misalignments can throw off their cutting ability. Professionals carefully examine the blade angles, sharpen the edges, fine-tune the tension screws, and test their performance to guarantee smooth operation [4].

Repair technicians aim to retain the original design and functionality of the shears while addressing any damage. This is especially critical for high-end shears made from premium Japanese steel, which demand expert handling to preserve their precision [3].

Fixing Cracks, Dents, and Loose Parts

Structural issues call for advanced repair methods to restore the shears' durability. Professionals can address a variety of problems:

| Damage Type | Repair Method and Outcome |

|---|---|

| Small Dents | Precision hammering to realign blades |

| Loose Screws | Replacing screws for stability |

| Minor Cracks | Welding to strengthen the structure |

| Handle Issues | Adjustments to improve functionality |

However, not all damage is fixable. For severe issues, like snapped blades or broken handles, replacement may be the only solution [4].

"Professional repair is essential for restoring damaged shears" [3].

Knowing these repair techniques underscores the value of proper care to avoid future issues.

Tips to Prevent Damage to Your Shears

Taking steps to protect your shears can save you money and hassle in the long run. For hairstylists, keeping these tools in top condition involves proper storage, regular upkeep, and smart buying choices.

Store Shears Safely

The right storage can prevent drops and scratches, keeping your shears in great shape:

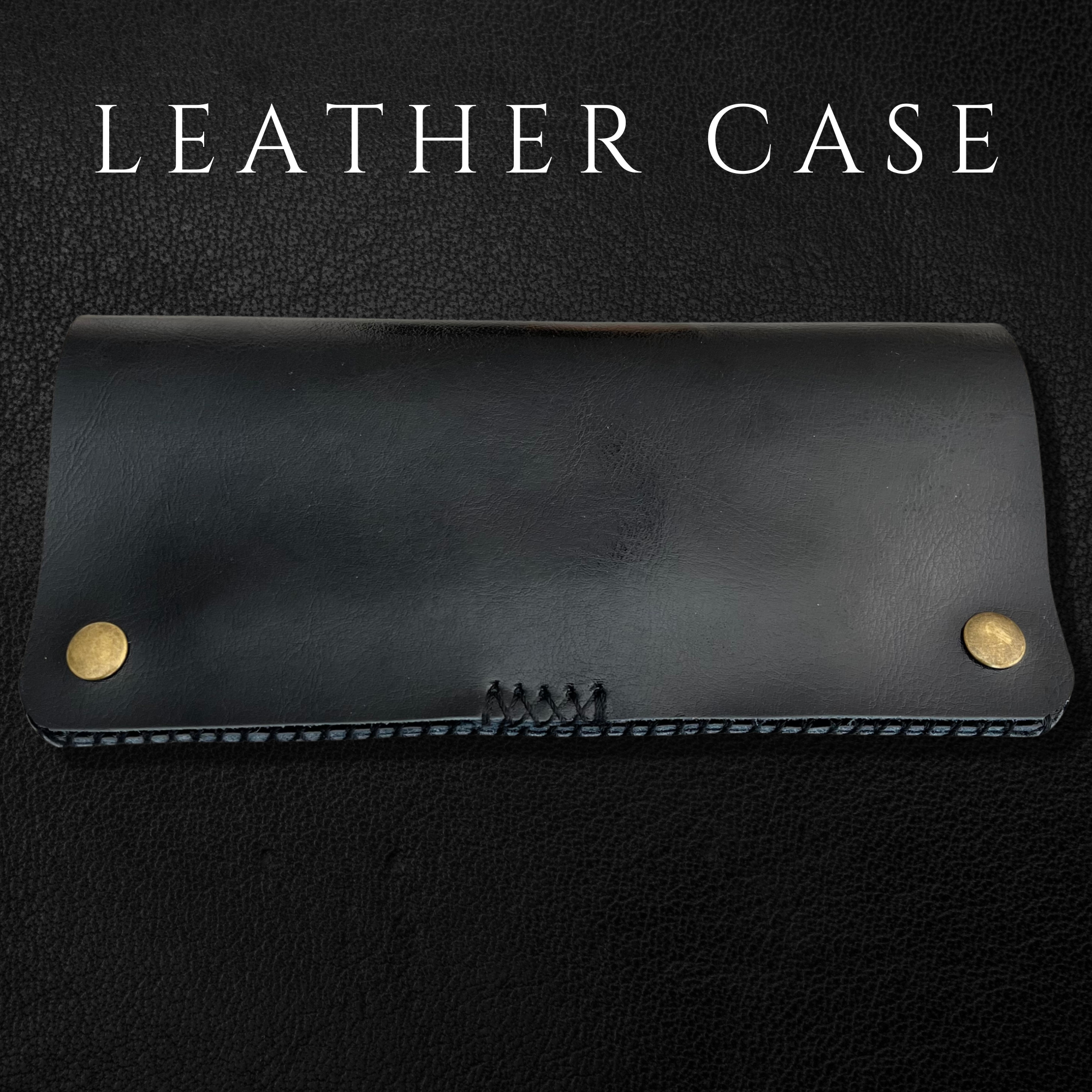

| Storage Method | Benefits | Ideal For |

|---|---|---|

| Scissor Holsters | Convenient access while working | Active styling sessions |

| Protective Cases | Shields against scratches and drops during travel | Transport and storage |

| Wall-mounted Holders | Maximizes space and keeps tools visible | Salon organization |

Regular Cleaning and Maintenance

Keep your shears performing well by cleaning them after each use, lightly oiling the pivot area, checking the tension, and storing them in a dry spot to avoid rust.

"Daily cleaning with a soft cloth and occasional oiling can help maintain the shears" [4].

Invest in High-Quality Shears

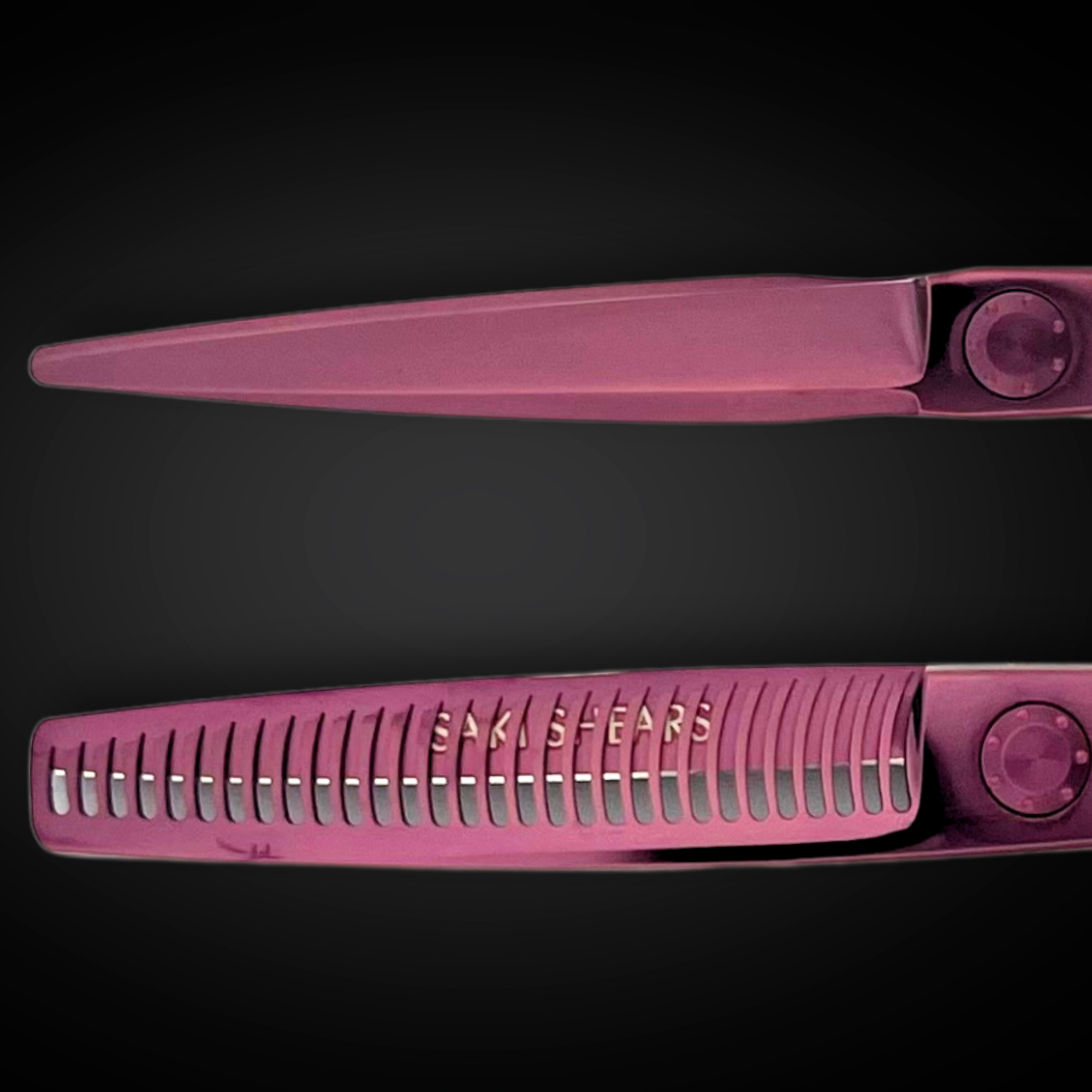

Spending on high-quality shears pays off with better durability and performance. Brands like Saki Shears offer features such as Japanese steel construction and ergonomic designs to reduce wear and tear. Key features include:

| Feature | Advantage |

|---|---|

| Japanese Steel Construction | Increased durability |

| Ergonomic Design | Better grip and reduced drop risks |

| Adjustable Tension | Ensures consistent performance |

| Lifetime Warranty | Added long-term value |

Conclusion: Caring for Your Shears After a Drop

Dropping your hair shears can be nerve-wracking, but acting quickly can help reduce damage and keep them working well. Start by carefully opening and closing the blades to see if they feel misaligned or resistant [1][4].

Here’s a simple guide to check your shears after a drop:

| Assessment Step | Action Required | When to Seek Professional Help |

|---|---|---|

| Visible Damage | Look for dents or cracks | If you notice any structural issues |

| Blade Alignment | Test opening/closing motion | If there’s a "jump" or resistance |

| Edge Inspection | Check for chips or burrs | If you see nicks or dull edges |

The quality of your shears plays a big role in how well they handle drops. Tools made from durable materials, like Japanese steel, are more likely to hold up after accidents. Brands like Saki Shears, known for their precision and strong Japanese steel construction, are a solid choice for professionals who need reliable tools.

If your inspection reveals any problems, a repair expert can address most issues with accuracy [1][4]. Regular upkeep and safe storage also go a long way in keeping your shears dependable over time. With quick post-drop care and consistent maintenance, you can extend the life of your tools and keep them performing at their best.

FAQs

What happens if you drop your shears?

The extent of damage from dropping your shears depends on how far they fall and what they hit. It's important to check them right away to prevent further issues.

| Type of Damage | Signs | Action Required |

|---|---|---|

| Blade Damage | Chips, dents, or burrs | Stop using immediately |

| Alignment Issues | Resistance or uneven motion | Avoid forcing blades |

| Structural Problems | Loose screws, bent parts | Get professional repair |

Here are some warning signs to look out for:

- Odd crunching noises while cutting

- Visible dents or misaligned blades

- Difficulty opening or closing the shears

If you notice any of these, stop using the shears right away to avoid making the problem worse - or causing discomfort to clients. While high-quality shears, like those crafted from Japanese steel, are more resistant to damage, they still need inspection after a drop [3].

As highlighted earlier, acting quickly and seeking professional care is key to keeping your shears in good condition after an accident [4]. Regular maintenance and check-ups by a professional can reduce the risk of damage and extend the lifespan of your tools [3][4].