How to Adjust Shear Tension Correctly

Proper shear tension is essential for clean cuts, tool longevity, and reducing hand fatigue. Incorrect tension can lead to uneven cuts, tool damage, and discomfort. Here’s a quick guide to get it right:

- Loose Tension Symptoms: Hair folds, uneven cuts, blades close on their own.

- Tight Tension Symptoms: Stiff blades, quick hand fatigue, squeaking during use.

-

Adjustment Steps:

- Clean and oil the shears.

- Use the tension screw to tighten or loosen slightly.

- Perform the 90-degree test: blades should stop at a 10-30° angle when released.

- Maintenance Tips: Check tension daily, clean and lubricate regularly, and store shears in a cool, dry place.

Investing in high-quality shears, like those made from Japanese steel, ensures better tension stability and longer-lasting performance. Regular checks and adjustments will keep your tools sharp and effective.

How to Adjust Professional Hair Scissors Tension

Basics of Shear Tension

Getting the tension right on your cutting tools is essential for both performance and durability. Proper tension ensures cleaner cuts and helps extend the life of your shears.

Symptoms of Incorrect Tension

Here’s how to spot if your shear tension is off:

Loose Tension:

- Hair folds or bends instead of being cut cleanly.

- Blades close completely on their own when released.

- Cuts appear uneven or have jagged edges.

- You hear a rattling noise while using the shears.

Tight Tension:

- Shears feel stiff or resistant when opening and closing.

- Your hand and wrist tire quickly during use.

- Smooth cutting motions become harder to maintain.

- Shears may squeak while in operation.

Risks of Incorrect Tension

Changes in temperature and humidity can affect shear tension, which is why regular checks are a must - especially for tools made from materials other than high-quality Japanese steel. Shears crafted from Japanese steel tend to hold their tension longer and need fewer adjustments [3].

Impact on Tools:

- Blades wear out faster.

- Components may become misaligned.

- The steel can degrade over time.

- Damage to the pivot joint is more likely.

Impact on Performance:

- Cutting accuracy is reduced.

- There’s a higher risk of strain injuries.

- Tasks take longer to complete.

- The overall lifespan of the tool decreases.

"Proper shear tension minimizes hand fatigue, reduces strain, and prevents repetitive injuries by enabling smooth, efficient cutting."

These risks highlight why adjusting tension correctly is so important. The next section will dive into how to do this effectively.

How to Adjust Shear Tension

Now that you know the risks of incorrect tension, let’s dive into how to adjust your shears for peak performance.

Preparing Shears for Adjustment

Before making any adjustments, start by cleaning your shears thoroughly. Use a lint-free cloth to remove hair, debris, or old lubricant from the blades and pivot area. Once clean, apply 1-2 drops of shear oil to the pivot joint to ensure smooth operation.

Adjusting the Tension Screw

The tension screw, located at the pivot joint, allows you to fine-tune the shears. Follow these steps for precise adjustments:

- Hold the shears vertically.

- Keep the finger handle steady while lifting the thumb handle.

- Turn the tension screw clockwise to tighten or counterclockwise to loosen.

- Make small adjustments, turning the screw no more than 1/8 of a turn at a time.

Note: If the screw resists turning, don’t force it. This could damage the shears. In such cases, seek professional servicing.

Checking the Adjustment

The 90-degree opening test is a reliable way to check if your tension is set correctly. Here’s how to do it:

1. Initial Position Test

Hold the finger ring securely with the blade pointing straight up. Open the shears to a 90-degree angle so the moving blade is horizontal, then release it gently.

2. Observe the Drop

The blade should move smoothly and stop just before fully closing, leaving a small gap between the blade tips.

3. Final Check

- If the blades close completely, the tension is too loose.

- If the blades barely move or stay fully open, the tension is too tight.

- The ideal setting is when the blades stop at a 10-30 degree angle.

For best results, perform this test before each use. Regular checks and adjustments will help maintain the performance and lifespan of your shears.

| Tension State | Blade Movement | What to Do |

|---|---|---|

| Too Loose | Closes fully | Tighten screw (clockwise) |

| Too Tight | Barely moves | Loosen screw (counterclockwise) |

| Just Right | Stops at 10-30° | No changes needed |

Once you’ve adjusted the tension, you’re ready to tackle any persistent issues that might come up.

Solving Tension Problems

Adjusting Loose or Tight Tension

Here’s how to handle tension issues effectively:

To fix loose tension:

- Hold the shears vertically with the tip pointing upward.

- Turn the tension knob clockwise 1-2 clicks.

- Open the shears to a 45-degree angle and check if the blades stay in position.

- Repeat as needed until the blades hold steady at the 45-degree mark [2].

To correct tight tension:

- Start with the shears in the same vertical position.

- Turn the tension knob counterclockwise gradually.

- Aim for blade movement between 55 and 65 degrees.

- Test by cutting hair to ensure smooth operation [3].

| Tension Issue | Adjustment | Test |

|---|---|---|

| Loose | Turn knob clockwise 1-2 clicks | Blades stay at 45° |

| Tight | Turn knob counterclockwise gradually | Blades move 55-65° |

If the blades still slip or tension problems persist, it could point to deeper issues that need attention.

Handling Slipping Blades

Regular maintenance is essential for avoiding blade slippage [3].

Professional-grade shears with locking tension systems help maintain stability and reduce the need for frequent adjustments [3][1].

When dealing with persistent slipping, consider these factors:

- Humidity: Environmental conditions like high humidity can affect shear tension.

- Pivot joint quality: Worn or low-quality parts may cause instability.

- Shear age and wear: Older tools may need more frequent adjustments or replacement.

- Damage: Previous drops or impacts can lead to alignment issues.

sbb-itb-337cfe6

Maintaining Shear Tension

Once you've resolved tension issues, keeping up with regular maintenance is key to ensuring long-term performance and avoiding recurring problems.

Regular Tension Checks

Make it a habit to check your shear tension daily for consistent performance. For professional stylists and barbers, these checks should be part of your morning routine and done after cleaning sessions to keep your cuts precise.

Here’s how to properly check tension:

- Open the shears to a 45-degree angle and see if the blades stay in place.

- Test their cutting action on a small section of hair.

- If needed, make minor adjustments to fine-tune the tension.

In addition to daily checks, remember to clean and lubricate your shears after every use, perform a deeper cleaning weekly, and schedule professional servicing every 6-12 months. These small steps go a long way in maintaining consistent performance throughout your workday.

External factors, like humidity and temperature, can also play a role in tension stability, so it’s worth keeping an eye on these as well.

Impact of Environment on Tension

Changes in humidity and temperature can cause your shears to tighten or loosen unexpectedly. To counteract this, store them properly and adjust the tension as needed.

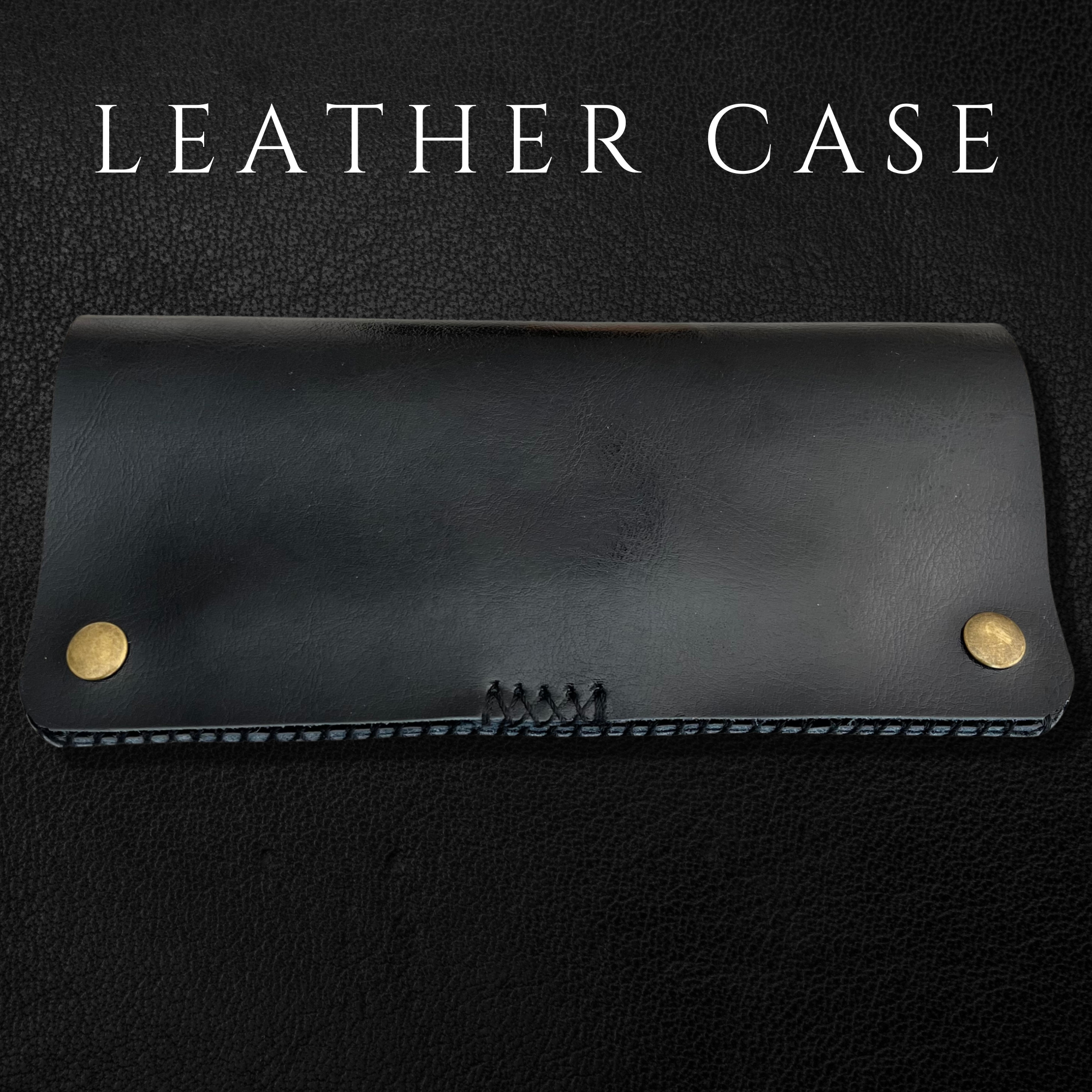

Here are some tips to protect your shears from environmental effects:

- Keep them in a cool, dry place, away from direct heat or sunlight.

- Use protective cases designed to absorb moisture.

- Make small adjustments to the tension to account for environmental shifts.

Shears made from high-quality materials are generally less sensitive to these changes. Letting your shears adjust to room temperature before making any tension tweaks also helps.

"Regular lubrication is crucial for maintaining shear tension and extending tool longevity. It also helps in maintaining the correct tension by preventing the buildup of debris and corrosion" [2][3].

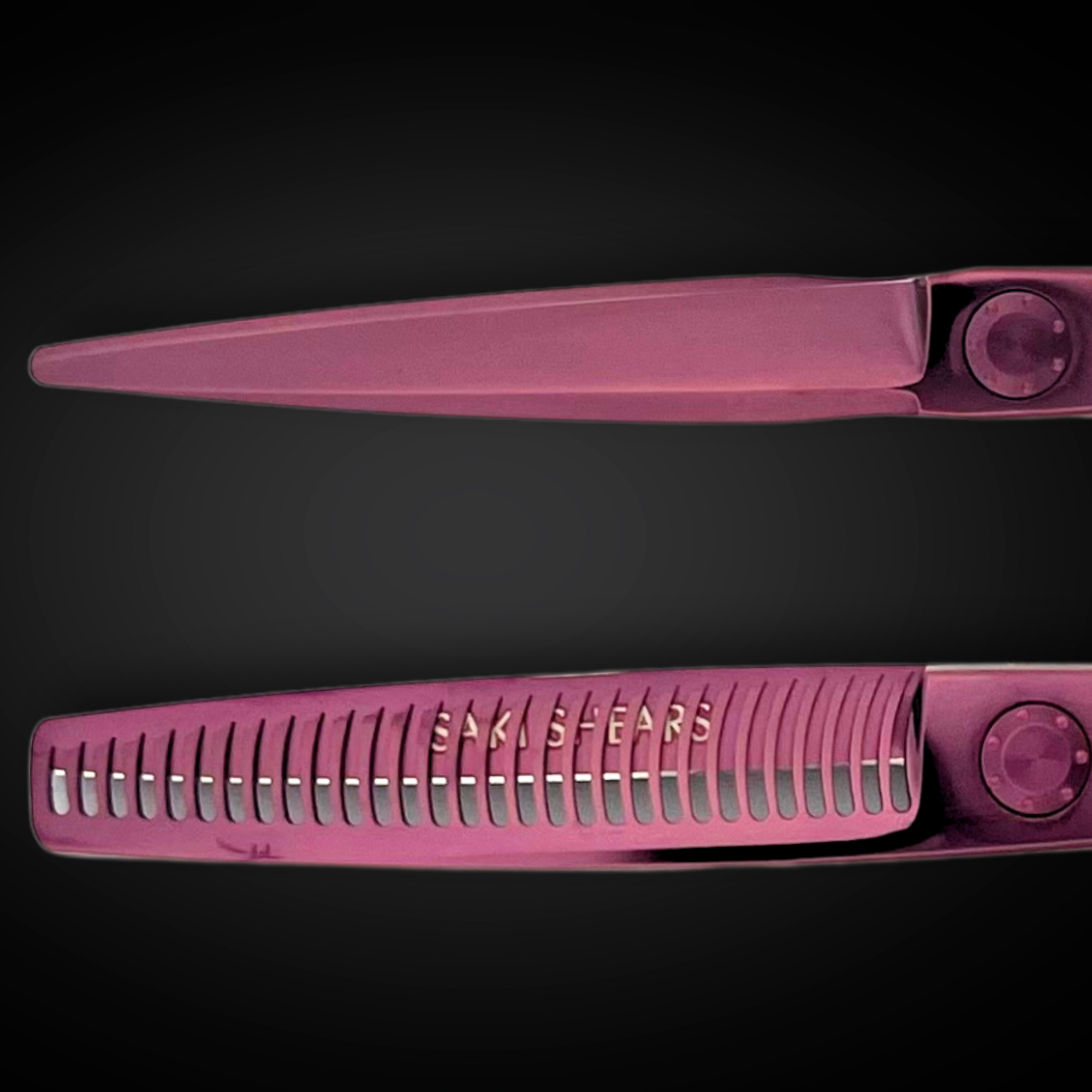

Choosing Quality Shears for Tension Control

Shears made from Japanese steel often feature advanced tension systems, allowing for precise adjustments that last. These tools are a must-have for keeping cutting performance sharp while minimizing upkeep.

Why Professional Shears Stand Out

Shears crafted from Japanese steel offer several benefits when it comes to tension control:

- Durable material: Japanese steel resists wear, maintaining tension stability over time.

- Precision mechanisms: Built-in systems allow for accurate and steady tension adjustments.

- Comfortable design: Ergonomic shears ease hand strain, even during frequent adjustments.

"Regular lubrication and proper tension adjustment are essential for maintaining optimal performance. When paired with Japanese steel, these practices extend shear lifespan", says Andrew Carruthers, Education Director for Sam Villa [2].

The Value of a Lifetime Warranty

Shears with advanced tension systems typically range from $180 to $300, but they offer lasting benefits:

- Coverage for tension systems and access to expert repairs.

- Protection against defects in materials or manufacturing.

- Fewer adjustments needed over time.

- Lower overall maintenance costs.

- Reliable cutting performance.

- A longer lifespan for your tool.

For the best results, choose shears with adjustable tension systems, ergonomic handles, and strong materials like Japanese 440C or VG-10 steel.

Investing in high-quality shears not only makes tension adjustments easier but also ensures consistent performance and durability for years to come. Tools like these are essential for professionals who demand reliability and precision.

Conclusion: Achieving Optimal Shear Performance

This guide has highlighted how proper tension adjustment and regular maintenance are key to keeping your shears performing at their best. Adjusting the tension correctly ensures smooth, clean cuts, reduces strain on the tool, and extends its lifespan - goals every professional values.

Shears made from Japanese steel with advanced tension systems provide excellent control and stability. These tools hold their settings longer and require fewer adjustments, making them a smart choice for professionals who demand reliability. Regular checks and precise adjustments with the right tools are essential for consistent cutting results.

To keep your shears in top shape, focus on three key habits: checking the tension regularly, cleaning them properly, and storing them with care. These steps not only improve tool performance but also significantly extend their lifespan. Neglect, on the other hand, can lead to premature wear and replacement.

High-quality shears with advanced tension features make maintenance easier. Combined with regular cleaning, lubrication, and attention to storage conditions, these tools deliver dependable results and improve the quality of your work. Adding tension checks to your routine ensures your tools remain sharp and effective.

Learning how to adjust tension properly is an investment in both your tools and your craft. By choosing quality tools and making tension adjustment a priority, you'll work more efficiently, protect your equipment, and take your skills to the next level.

FAQs

What happens when shear scissor tension is too loose?

When the tension is too loose, the blades don’t make proper contact, which affects cutting quality. This is often mistaken for dull blades. Signs of loose tension include uneven cutting and extra effort needed during use.

How to make scissors less stiff?

To adjust stiff scissors, follow these steps:

- Hold the scissors upright with the blades pointing up, and locate the tension adjustment screw.

- Turn the screw slightly counterclockwise to loosen the tension.

- Test the scissors after each adjustment to ensure the tension feels right.

When adjusted correctly, the blades should stay open at about a 45-degree angle when released.

Quick Tips for Adjusting Tension:

- Make small adjustments to avoid over-loosening.

- Clean and oil the scissors before making changes.

- Check the tension often while adjusting.

Improper tension can cause your scissors to wear out faster and impact their performance. High-quality scissors with advanced tension systems tend to hold their settings longer and deliver more reliable results.