7 Common Disinfection Mistakes with Hair Tools

Proper disinfection of hair tools is critical for client safety, tool longevity, and maintaining your professional reputation. Here are the most common mistakes to avoid:

- Skipping Pre-Cleaning: Residue on tools blocks disinfectants, leading to ineffective cleaning and potential corrosion.

- Using the Wrong Disinfectants: Different materials require specific disinfectants. For example, high-quality Japanese steel tools need pH-balanced solutions.

- Not Allowing Enough Soaking Time: Cutting disinfection time short leaves harmful pathogens behind.

- Improper Cleaning of Electric Tools: Treating electric tools like non-electric ones risks short circuits and motor damage.

- Storing Wet Tools: Moisture causes rust and fosters bacteria growth.

- Reusing Disposable Items: Single-use items must be discarded after use to prevent cross-contamination.

- Ignoring Blade Damage: Cleaning is a perfect time to inspect blades for chips, cracks, or dullness.

Quick Tip: Always follow manufacturer guidelines, use EPA-approved disinfectants, and dry tools thoroughly to extend their lifespan and ensure safety.

Hairstylist 101: Cleaning Your Combs, Brushes, Clips, Shears, etc. (Talk-Thru)

1. Not Cleaning Tools Before Disinfecting

Skipping the step of pre-cleaning before disinfecting your tools can lead to damage and reduce the effectiveness of your disinfection routine.

Why Pre-cleaning Is Important

Any debris left on tools can act as a barrier, stopping disinfectants from reaching harmful microorganisms. If residue remains on shears or styling tools, it creates a shield for bacteria and pathogens, rendering disinfection ineffective.

How It Affects Your Tools

Failing to pre-clean can cause:

- Corrosion on metal surfaces

- Dull cutting edges

- A shorter lifespan for your tools

Steps for Proper Pre-cleaning

- Use a lint-free cloth to wipe away visible debris

- Apply a pH-balanced cleaning solution

- Rinse thoroughly and dry completely

This step ensures your tools are ready for effective disinfection.

Extra Care for High-End Tools

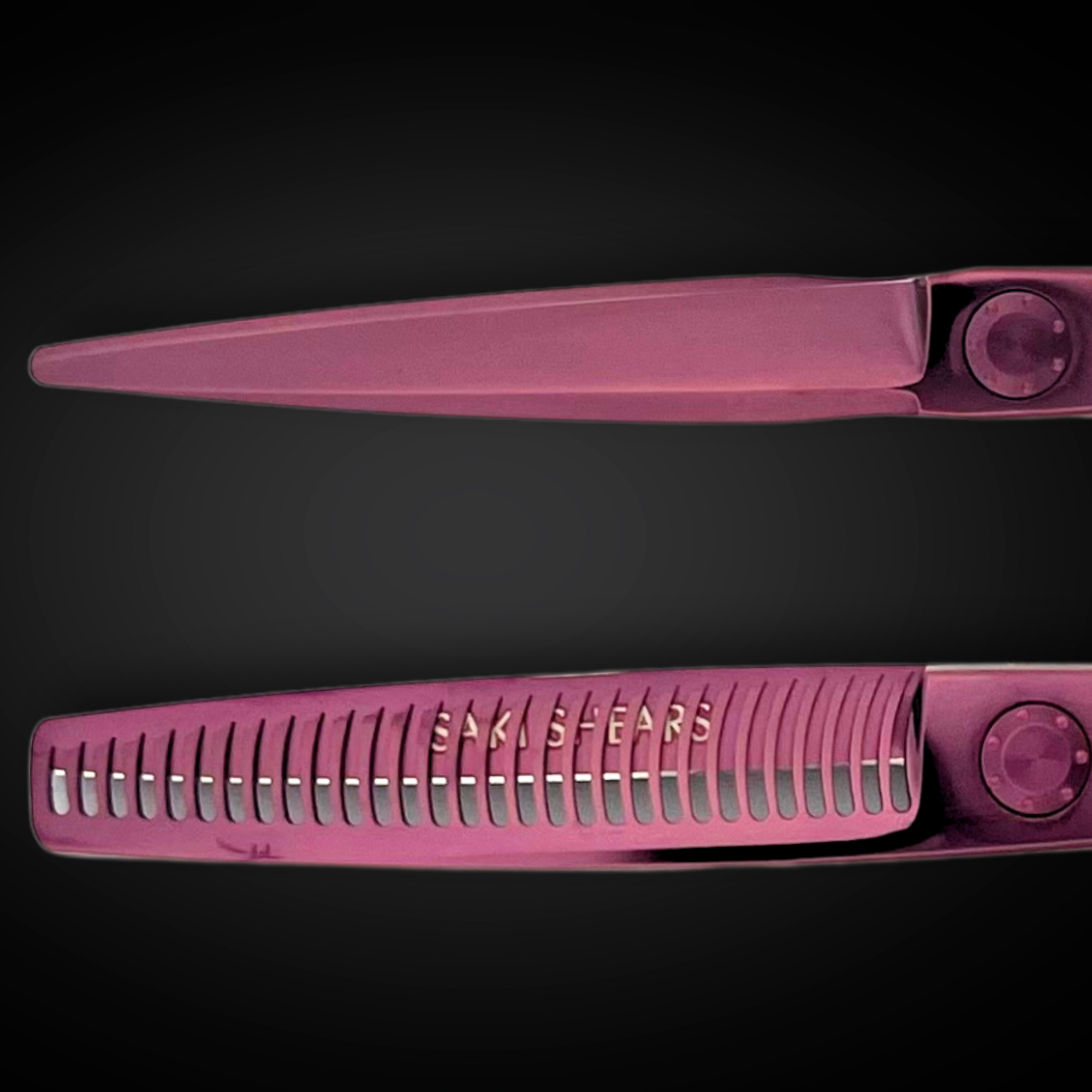

If you’re working with premium Japanese steel tools, like those from Saki Shears, proper maintenance is especially important. By following these pre-cleaning steps, you can maintain blade sharpness and protect your investment.

2. Using the Wrong Disinfectants for Different Materials

Choosing the wrong disinfectant can harm your tools and reduce its cleaning effectiveness. Different materials require specific disinfectants to ensure proper sanitization without causing damage.

Material-Specific Guidelines

Professional tools are made from a variety of materials, each needing specific care. For example, high-quality Japanese steel shears, like Saki Shears, require pH-balanced disinfectants to avoid corrosion and maintain their sharpness. Other tools may react poorly to certain chemicals, so always check the manufacturer's recommendations to prevent material damage.

Signs Your Disinfectant Is Causing Damage

Look out for these signs that your disinfectant might be harming your tools:

- Metal that appears dull or pitted

- Plastic that looks bleached or discolored

- Sticky residue or unusual odors

- Rust or visible corrosion

Protecting Your Tools and Maximizing Their Lifespan

Using the wrong disinfectant not only reduces cleaning effectiveness but also shortens the life of your tools. Always check labels for compatibility, proper contact times, and correct dilution ratios. These simple steps can help protect your investment in professional tools and ensure safe, high-quality service for your clients.

Up next, find out how improper cleaning of electric tools can compromise their safety.

3. Not Allowing Enough Soaking Time

Disinfectants need to stay in contact with hair tools for the full time specified by the manufacturer. Cutting this step short reduces the disinfectant's effectiveness, leaving harmful pathogens behind and increasing the risk of cross-contamination.

Why Soaking Time Matters

Every disinfectant has specific instructions for use. The contact time listed on the product label or safety data sheet (SDS) tells you how long tools need to stay immersed to ensure proper disinfection. Skipping or rushing this step compromises the solution's ability to do its job.

What happens if soaking time is too short?

- Pathogens may survive on the tools

- Cross-contamination risks increase

- You could violate health regulations

- Infection risks for clients and staff rise

Tips to ensure proper disinfection:

- Keep multiple tool sets available so you always have clean tools ready to use

- Use digital timers to track the soaking time accurately

- Create a dedicated disinfection area with clearly labeled containers

Next, we'll look at how to handle cleaning challenges with electric tools.

4. Improper Cleaning of Electric Tools

Electric hair tools need special care during cleaning because they are sensitive to moisture. Treating them the same as non-electric tools can lead to issues like short circuits, motor failure, rust, and a shorter lifespan.

Why Improper Cleaning Is Risky

Here’s what can go wrong with poor cleaning practices:

- Liquid can seep inside, causing short circuits

- Motors can get damaged by moisture exposure

- Internal parts may corrode over time

- Safety hazards from electrical malfunctions

- Overall durability of the tool can decline

To avoid these problems, electric tools need specific cleaning methods.

How to Clean Electric Tools Safely

Follow these steps to disinfect your tools without damaging them:

-

Detach Removable Parts

Take off any parts that can be removed, like guards or filters, and clean them separately using standard disinfectants. -

Handle the Main Unit Carefully

Never submerge the main unit in liquid. Unplug it, let it cool, and use EPA-approved disinfectant wipes to clean areas like vents and seams. Make sure it’s completely dry before putting it away.

Cleaning Tips for Different Tools

Here’s how to safely clean various electric hair tools:

| Tool Type | Safe Cleaning Method | Avoid: |

|---|---|---|

| Hair Dryers | Wipe the exterior and clean the removable filter | Submerging the unit or spraying liquids directly |

| Electric Clippers | Use a light disinfectant spray and brush between blades | Getting moisture near the motor or soaking parts |

| Hot Tools | Clean only when cool; wipe down the barrel or plates | Cleaning while hot or letting liquid near the cord |

Important Safety Reminders

- Always check the manufacturer’s cleaning instructions for your specific tool.

- Never store tools while they’re still damp.

5. Putting Away Wet Tools

Storing tools while they're wet can ruin them quickly. Moisture causes rust to form on metal parts and encourages bacteria to grow in damp areas. This not only damages the tools but also shortens their lifespan.

Here’s how to properly dry your tools to keep them in good condition:

- Wipe Off Water: Use a lint-free towel to remove as much water as possible right away.

- Air Dry Completely: Place the tools on a clean, absorbent surface in a well-ventilated spot and let them dry fully.

- Inspect for Moisture: Check every part of the tool, including joints, blade edges, and handles, to make sure no moisture is left behind.

Taking these steps helps ensure your tools stay rust-free and ready for use.

6. Using Disposable Items Multiple Times

Reusing disposable tools compromises hygiene and increases the chance of cross-contamination and infections. Items meant for a single use - like neck strips, disposable razor blades, wax applicators, cotton swabs, and protective gloves - should always be discarded after use.

To keep hygiene standards high:

- Keep a stock of disposable items readily available.

- Store unused disposables in sealed, dry containers.

- Train staff on proper disposal procedures.

- Regularly review and document disposal protocols.

- Place clearly labeled disposal bins in work areas.

Along with following disinfection routines, properly discarding single-use items is a must. For professional tools like shears and razors, invest in durable, sanitizable options. These tools need to be cleaned and disinfected thoroughly between clients using EPA-registered disinfectants approved for salon use. For instance, Saki Shears provides top-quality shears made from premium Japanese steel, designed for long-lasting use and easy sanitization.

Failing to properly dispose of items not only risks hygiene but also damages your reputation and can lead to compliance issues.

Pro tip: Make disposal easier by placing clearly labeled bins in workspaces, and ensure staff training reinforces these essential practices.

7. Identifying Blade Damage During Cleaning

When cleaning your blades, take a moment to inspect them for any signs of damage. Ignoring damage can lead to uneven cuts and even pose a safety risk.

Here’s what to look for:

- Chips or cracks along the cutting edge

- Bends or misalignment between the blades

Use bright lighting to make your inspection easier. Afterward, perform a simple test cut to ensure the blade is both sharp and properly aligned.

| Step | Signs | Action |

|---|---|---|

| Visual Check | Chips, cracks, or bends | Stop using the tool and remove it from service immediately |

| Cutting Test | Uneven or imprecise cuts | Repair or replace the tool if needed |

Pro Tip: Always inspect and test your blades right after cleaning and disinfecting. If you spot any damage, don’t delay - remove the tool from use and arrange for professional repair or replacement.

For example, premium Japanese steel shears require consistent upkeep to retain their precision. Brands like Saki Shears even offer a lifetime warranty, showing their commitment to quality and long-term performance.

Up next, let’s dive into overall maintenance tips to help your tools last longer.

Disinfectant Guide for Hair Tools

Now that you're aware of common disinfection mistakes, use this guide to choose the right disinfectants for your hair tools.

Always pick EPA-approved disinfectants to ensure both safety and tool durability. The table below outlines how to use them and their compatibility with different materials.

| Disinfectant Type | Best For | Contact Time | Compatible Materials |

|---|---|---|---|

| Barbicide | Metal tools, combs, and brushes | 10 minutes | Safe for stainless steel and plastic |

| Quaternary Ammonium | Non-porous surfaces and metal tools | 10–15 minutes | Works well with premium metals |

| 70% Isopropyl Alcohol | Quick sanitizing and electric tools | 5–10 minutes | Generally safe for most materials |

| Hospital-grade EPA Solutions | A variety of professional tools | 5–15 minutes | Broad-spectrum, universal compatibility |

Electric Tool Safety

When disinfecting electric tools like clippers or trimmers:

- Use sprays or wipes instead of submersion.

- Keep all electrical components dry and ensure tools are completely dry before reassembly.

- Clean any removable parts separately for thorough sanitation.

Material-Specific Tips

High-quality metal tools, such as those made from premium Japanese steel (e.g., Saki Shears products), need extra care. Alcohol-based or specialized solutions work best to preserve their integrity and avoid corrosion.

Contact Time Is Key

Disinfectant contact time is critical. Too short, and pathogens may remain. Too long, and you risk damaging your tools. Stick to the recommended times for the best results.

Pro Tip: Use a timer during disinfection to ensure you're following the exact contact time for each product. This small step can save your tools and ensure proper sanitation.

Conclusion

Keeping your tools disinfected is essential for protecting your clients, your reputation, and the investment you've made in quality hair shears. High-quality shears are a big commitment, and proper care not only ensures safety but also significantly extends their lifespan. With consistent maintenance, premium tools can last 12–15 years instead of the typical 4–5 years, saving money and ensuring reliable performance.

Stick to these key steps: thoroughly pre-clean, use EPA-approved disinfectants, follow the recommended contact times, dry tools completely, and inspect them regularly. These habits are crucial for maintaining both your tools and your business.

Take Saki Shears as an example. Their professional-grade Japanese steel tools rely on proper disinfection to maintain their precision and durability. Following manufacturer guidelines and using the right cleaning products helps prevent corrosion and keeps blades sharp.

FAQs

Why should you use disinfectants designed for specific hair tool materials?

Using material-specific disinfectants is essential to protect both your tools and your clients. Hair tools are made from various materials, such as stainless steel, plastic, or rubber, and each material reacts differently to certain chemicals. Using the wrong disinfectant can cause damage like corrosion, discoloration, or weakened components, which can reduce the lifespan of your tools.

Additionally, improper disinfectants may fail to eliminate bacteria, viruses, and fungi effectively, posing a risk to your clients' health. By selecting disinfectants tailored to the materials of your tools, you ensure proper sanitation, maintain the quality of your equipment, and provide a safe experience for every client.

What is the best way to disinfect electric hair tools without damaging them?

To disinfect electric hair tools safely, always follow the manufacturer's cleaning instructions. Start by unplugging the tool and ensuring it has completely cooled down. Use a soft, damp cloth with a small amount of rubbing alcohol to gently wipe the surfaces, avoiding any electrical components or vents. For stubborn residue, a cotton swab dipped in alcohol can help clean hard-to-reach areas. Never immerse electric tools in water or use harsh chemicals, as this can cause damage or pose safety risks. Regular maintenance not only ensures proper hygiene but also extends the lifespan of your tools.

What happens if hair tools aren’t soaked for the full recommended disinfection time?

Failing to soak hair tools for the proper disinfection time can leave behind harmful bacteria, viruses, and fungi, which may spread infections to clients. Incomplete disinfection also compromises your compliance with health and safety regulations, potentially damaging your professional reputation. Always follow the manufacturer’s guidelines to ensure tools are thoroughly sanitized and safe to use.